Site Investigation

Site investigations assist to identify hazards at brownfield sites to aid reclamation. Investigations also assist engineers to assess physical conditions at sites of proposed construction for roads, bridges and buildings.Abandoned Mine Sites

Mine Closure Investigation

Other Waste Sites

Engineering Site Investigation (Characterization)

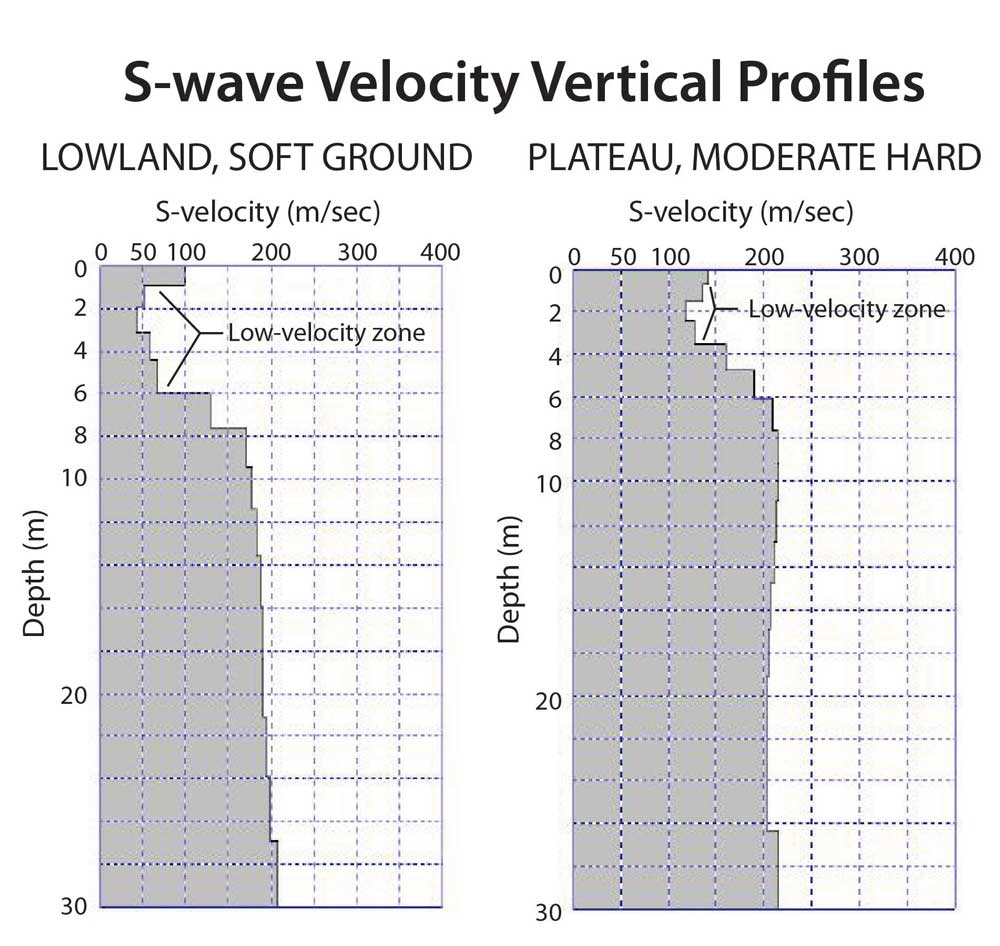

Seismic technologies have made great strides recently. Advances in computer processing, and understanding of p-wave, s-wave, and surface wave propagation have greatly expanded the knowledge, ability, and speed to assess the subsurface environment. Refraction surveys using p-wave energy is a well known method in assessment of rock hardness (rock strength), rippability, and subsurface mapping.MASW In 1-D

2-D Profiling With MASW

MASW seismic surveys are performed in a profile mode when several points are recorded in succession and later combined. Points may be along a straight or curved line, or crossing flat or difficult topography to investigate soil strength of engineering or wind energy sites, locate sinkholes, or assess building or road foundations. Surveys can be conducted within existing buildings. (Example 2

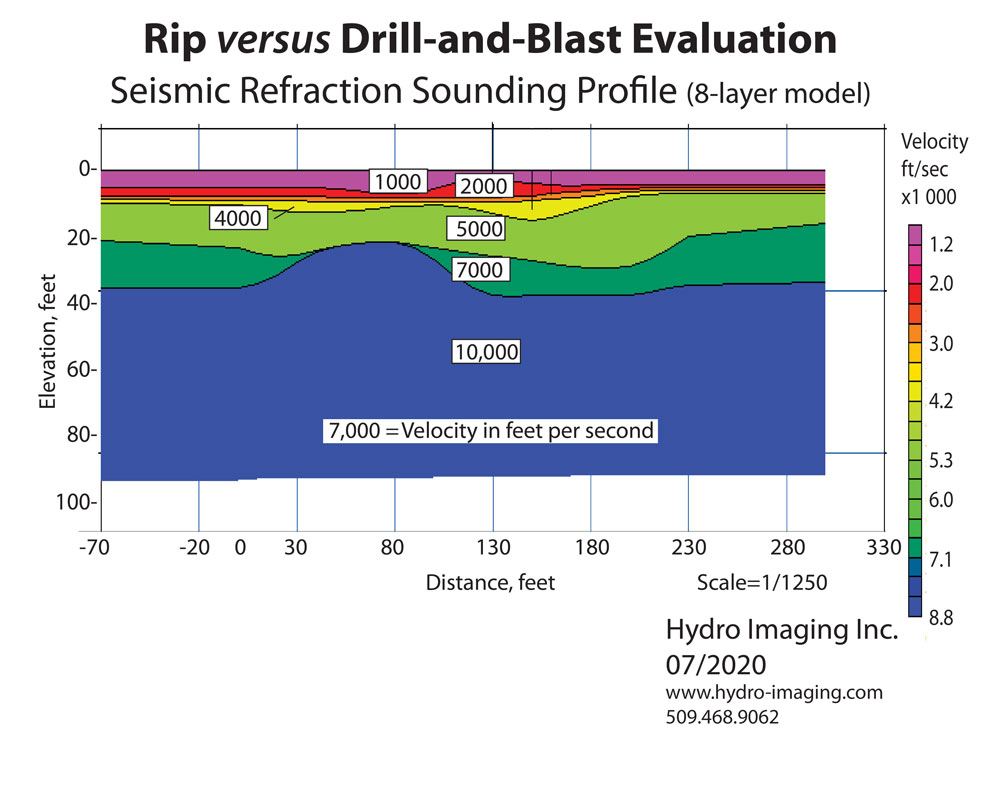

Engineering Site Investigations (Rip Instead of Drill and Blast)

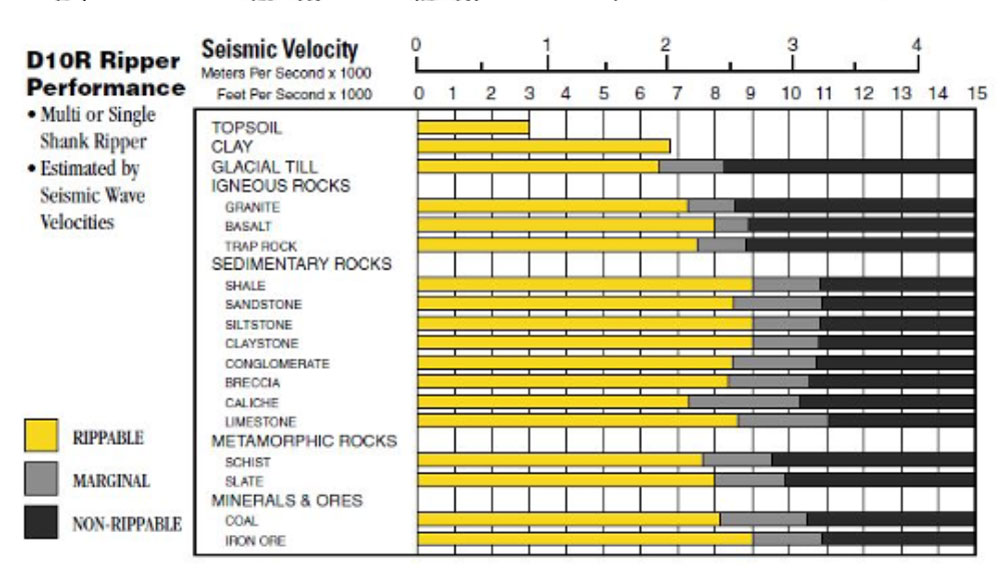

The Drill & Blast versus Rip decision can be made with aid of a seismic study using portable equipment and crew of two. This study involves minimal time, depending on a project scope, perhaps one field day for a small project. The seismic procedure involves use of seismic refraction gear.

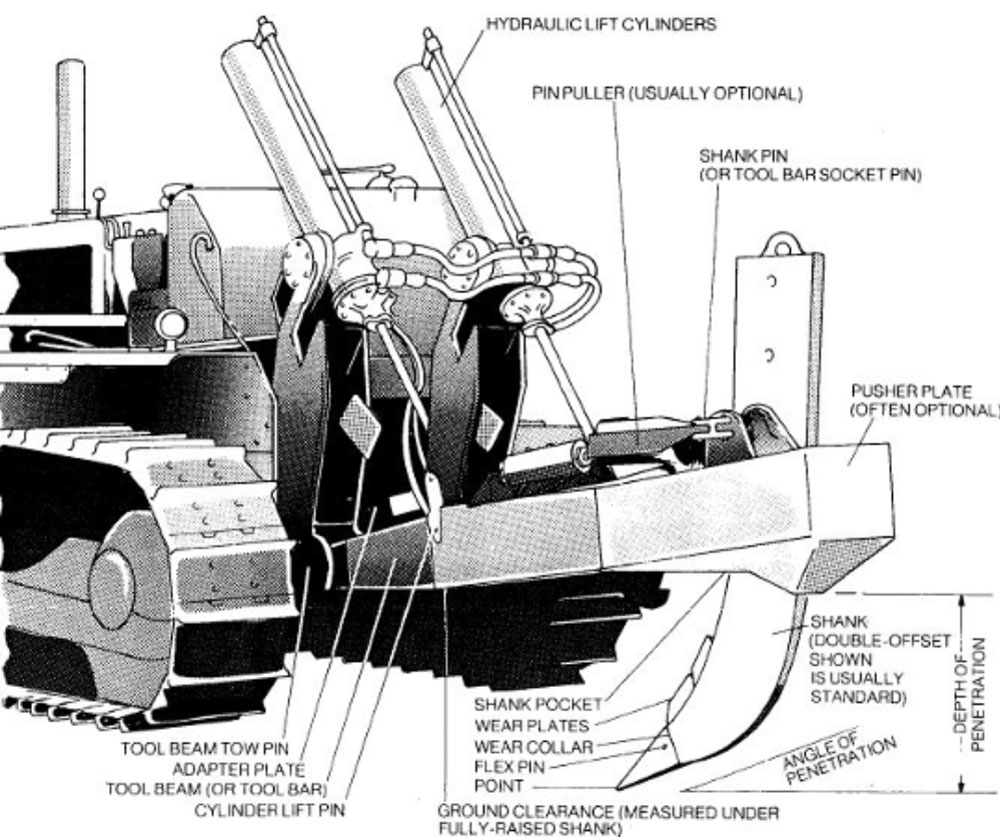

Ripping Handbook

Caterpillar has produced a “Handbook of Ripping” that details the ability of its crawlers equipped with ripping gear to penetrate rock. This performance handbook used in conjunction with newly acquired seismic information can be a big time savings and avoid a larger expense of drilling and blasting.

The D10 ripper performance can be estimated from the seismic results. The seismic results provide information about rock velocity, a measure of bulk density. The D10 tractor can rip overburden if seismic velocities are less than 7,000 feet per second (bulk density=2.18 g/cc) with relative ease or 9,000 feet per second (bulk density = 2.32 g/cc), depending on site conditions. (Caterpillar Handbook) Seismic Results

Seismic results from this evaluation shows changing velocity (or travel time) of sound through bedrock consisting of granite. Results show velocity of various rock units in feet per second (purple through blue). It shows that the granite at this site can be ripped using a D10 tractor equipped with ripper where rock velocity is 7,000 feet per second or less, corresponding to the green layers or shallower layers. This means that the maximum rippable depth is 37 feet. The rock units appear to granite having been subjected to varying degrees of weathering until hard bedrock is reached at 37 feet.